Find The Right Fit For The Job

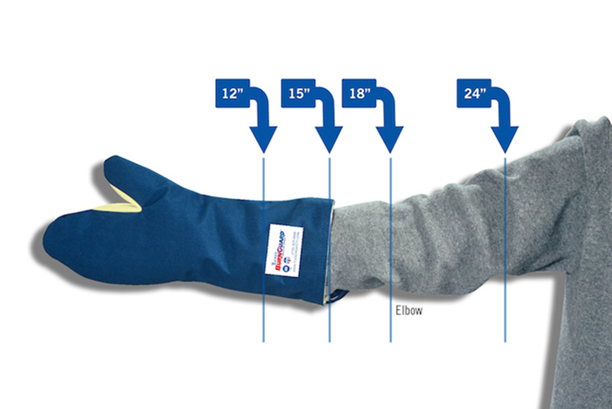

Protective apparel and properly fitting equipment are vital to the safety of the wearer. Knowing how to measure and choose mitt or glove sizes can increase safety, product effectiveness and productivity. To avoid injury and promote use and compliance, choose more than one size to accommodate different wearers.

Selecting Arm Length / Hand Size >

Burns: A Preventable Hazard

Burn Injuries Are Not Only Painful But Costly For Your Business!

Burn injuries are not only painful and costly for your business, leading to absenteeism, increased workers’ compensation costs, lower morale and increased turnover. When you think about it, upfront investment in Effective Protective Apparel™ is a small consideration compared to a single burn injury claim.

Burn Prevention >

Cut Resistance – the basics

The Right Cut Resistant Protection Makes a Difference

Cut resistant gloves and sleeves are designed to protect hands from direct contact with sharp objects such as glass and metal. The level of cut resistance provided is a combination of material composition and weight. Cut protection is improved by increasing its material weight by using high-performance materials such as Spectra or Dyneema, or by using composite yarns by combining stainless steel, fiberglass, synthetic yarns and high-performance yarns.

Selecting Cut Resistant Gloves >

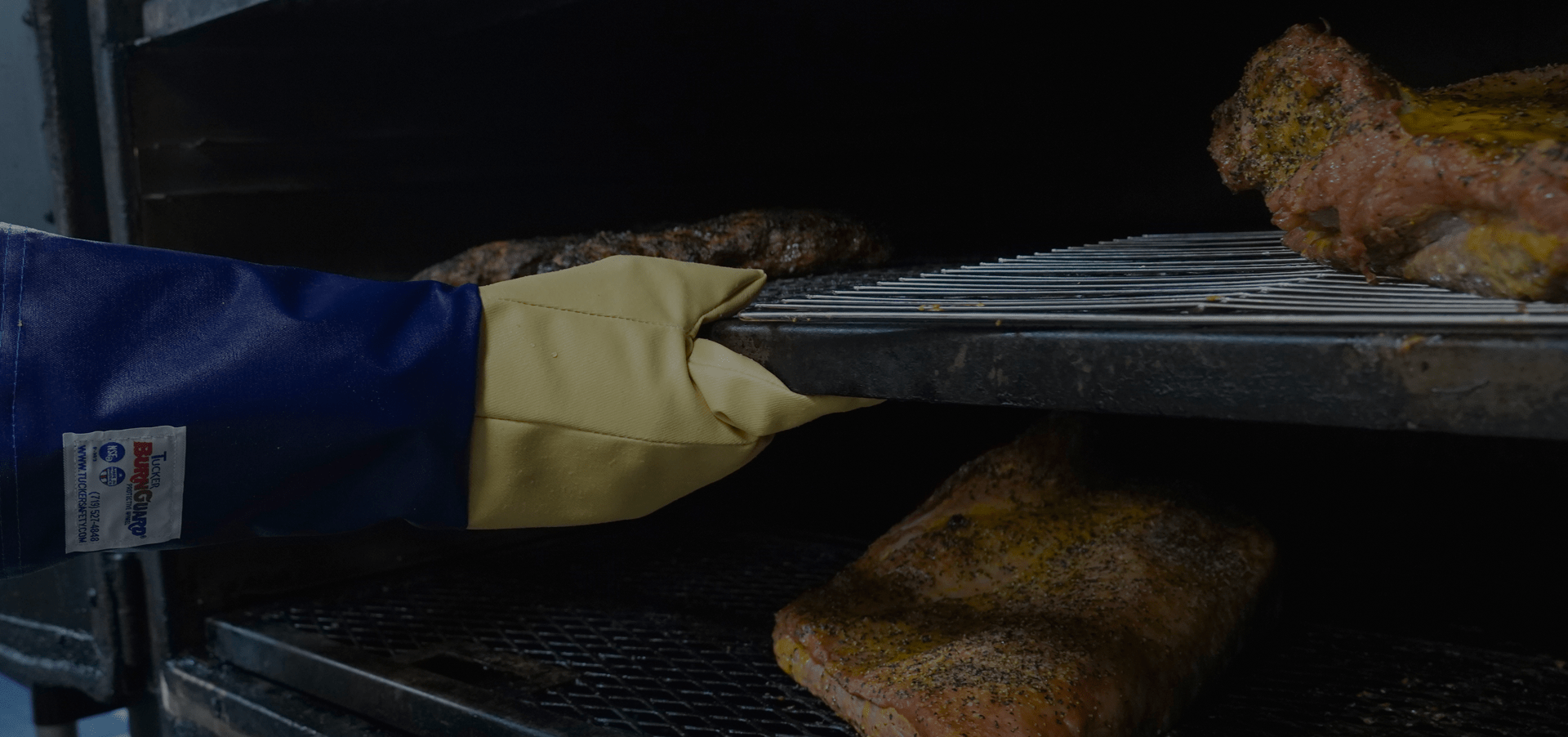

Choosing The Right Burn Protection

With the variety of tasks in every commercial kitchen, keeping staff safe from liquid, vapor and heat hazards requires a range of protection options. Review our guide for burn protection options to keep staff safe in your kitchen.

Choosing Burn Protection >

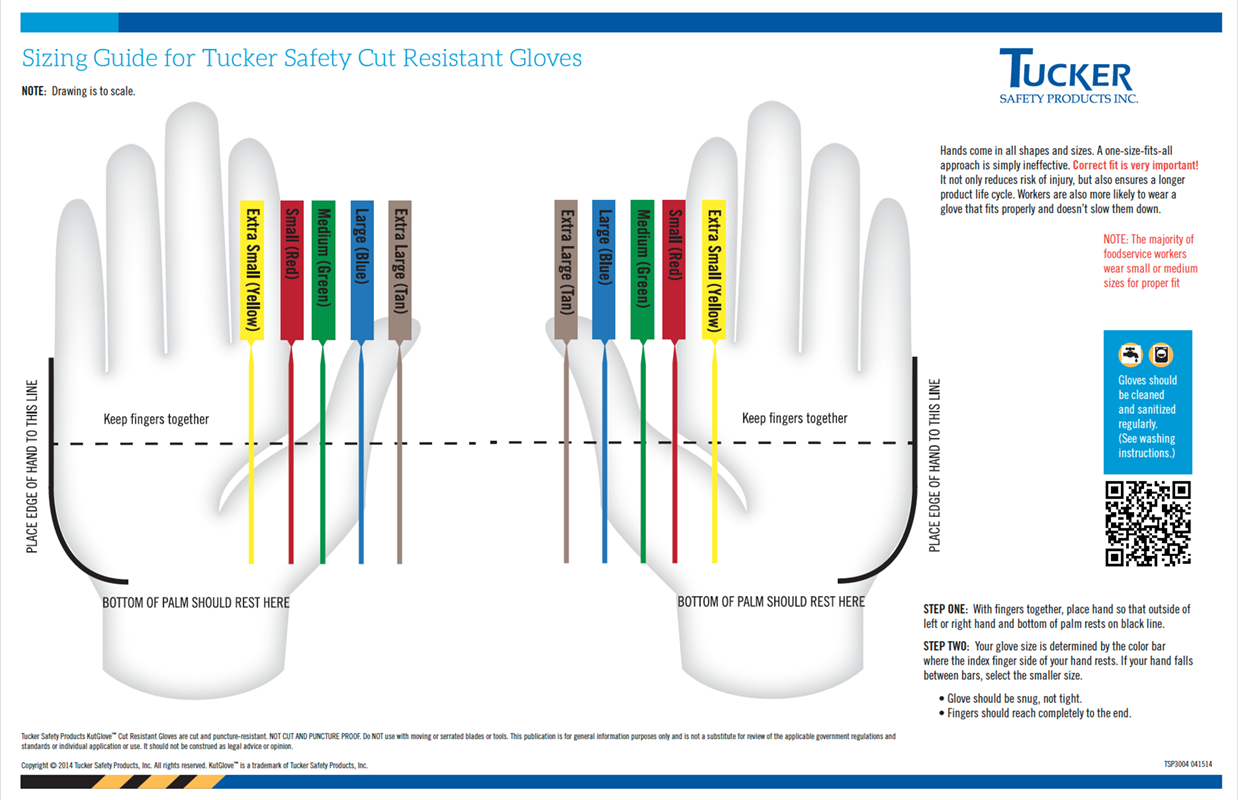

No Cut Protective Product Works If It Is NOT Worn!

Hands come in all shapes and sizes. A one-size-fits-all approach is simply ineffective. The correct fit is essential! It reduces the risk of injury and ensures a longer product life cycle. Workers are also more likely to wear a glove that fits properly and doesn’t slow them down.

Sizing Guide >

OSHA Safety Requirement Guides

Hazards exist in every foodservice operation in many different forms: hot liquids, grease, steam, hot surfaces, sharp objects/edges, falling objects, cleaning chemicals, and a myriad of other potentially dangerous situations.

The Occupational Safety and Health Administration (OSHA) has cited employers for not protecting their employees from workplace hazards that may be mitigated or eliminated through the use of PPE. OSHA’s coverage of PPE, however, is broad and relies heavily on American National Standards Institute (ANSI) voluntary standards. Keep in mind that OSHA standards are only minimum standards, and employers can implement more stringent requirements at their discretion.

Foodservice: Cuts Are Not On The Menu

Almost every commercial kitchen contains sharp objects or surfaces that can lead to cuts and lacerations. Knives, slicers and glassware are essential tools in most restaurants, elevating the risk of someone getting cut with a sharp blade or broken glass – it’s not surprising that cut and laceration injuries are a concern. Review cut protection safety tips to keep hands working and productive for a lifetime.

Cut Prevention >

Thermal Protection Is Critical For Burn Protection

Protecting commercial kitchen staff safe from liquid, vapor and heat hazards requires thermal protection. See how commercial quality protection is provided with a multi-layered construction.

Thermal Protection >

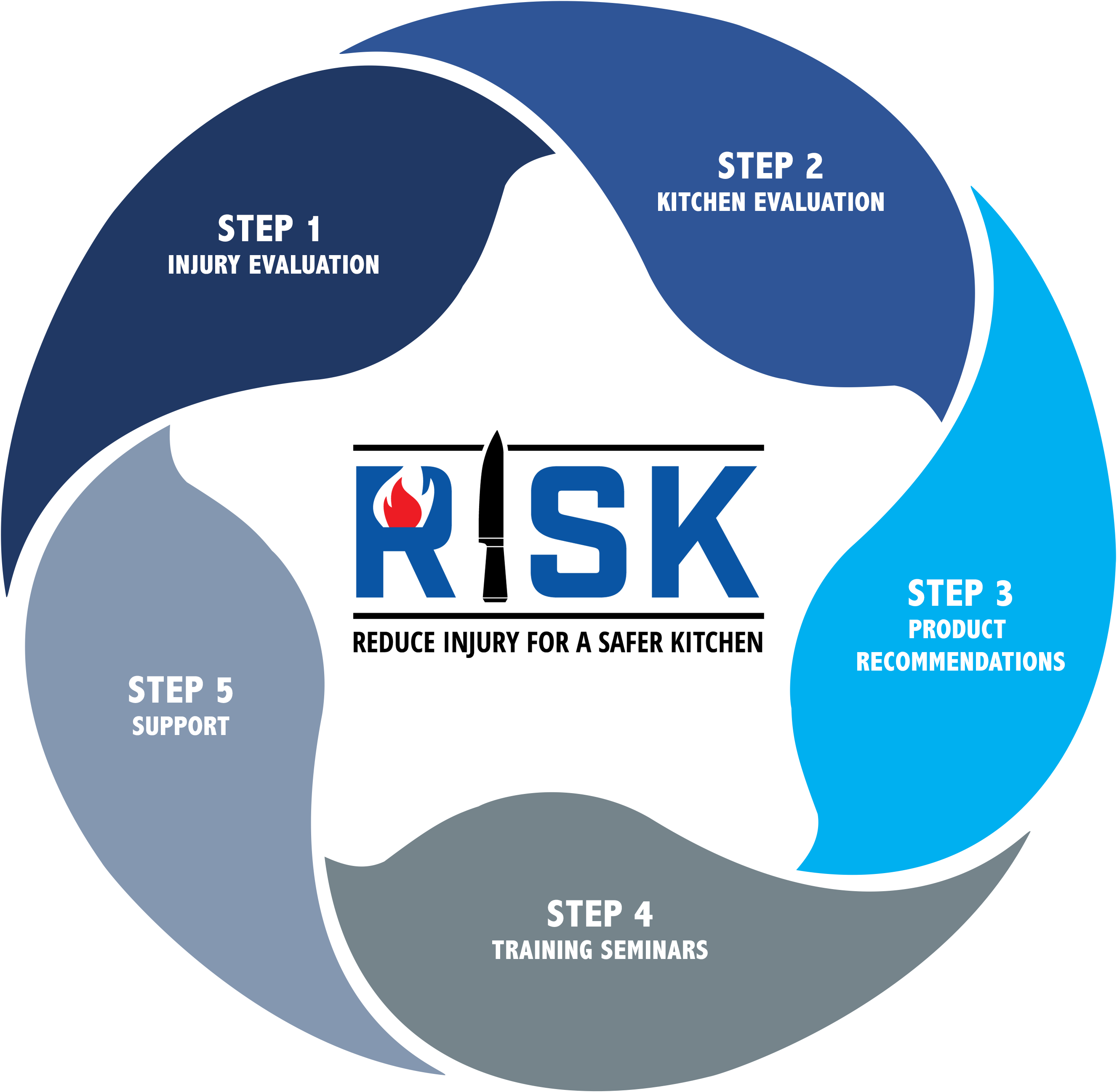

Injury Prevention Education

The Tucker RISK Assessment Program has helped many foodservice operators/owners evaluate their kitchen environments and ultimately avoid accidents or injuries before they occur. The SafeStep™ program can do the same for your business, whether you manage one or many locations.

Request A RISK Assessment Program Review>

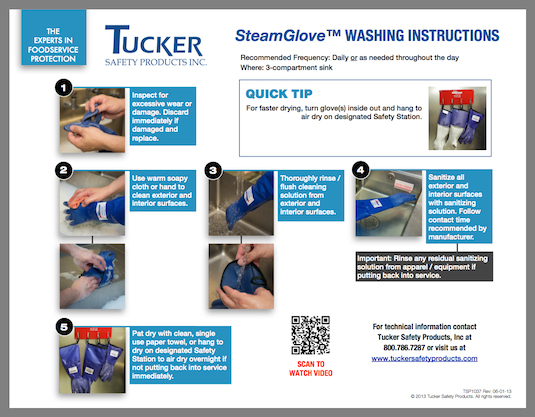

PPE Use Care | Job Aids Wall Charts

WASHING INSTRUCTIONS – Recommended Frequency: Daily, however clean as needed throughout the day

Job Aids Wall Charts >